Author: Jason Martin

Reviewed by: Supply Chain Solutions Lead

Last updated: September 30, 2025

Executive TLDR

-

Forecast the big rocks first, your top movers, then the rest.

-

Set one clean data set for demand, lead times, safety stock, and seasonality.

-

Use short review cycles, weekly for fast movers, monthly for long tail.

-

Tie your plan to inbound slots, storage space, cash, and carrier capacity.

-

Run a lightweight S&OP meeting that ends with clear purchase orders.

Need a fast demand plan you can trust — Contact Product Fulfillment Solutions

Table of contents

-

What demand planning really does

-

The 6 step demand planning playbook

-

Safety stock and service levels made simple

-

Turn the plan into inventory and space

-

Why Product Fulfillment Solutions

-

FAQ

What demand planning really does

Demand planning turns guesswork into a schedule. You line up expected orders, supplier lead times, and your cash. Then you decide what to buy and when to bring it in. For brands with fast moving consumables, good planning means fewer stockouts, less dead stock, and a smoother pick and pack day.

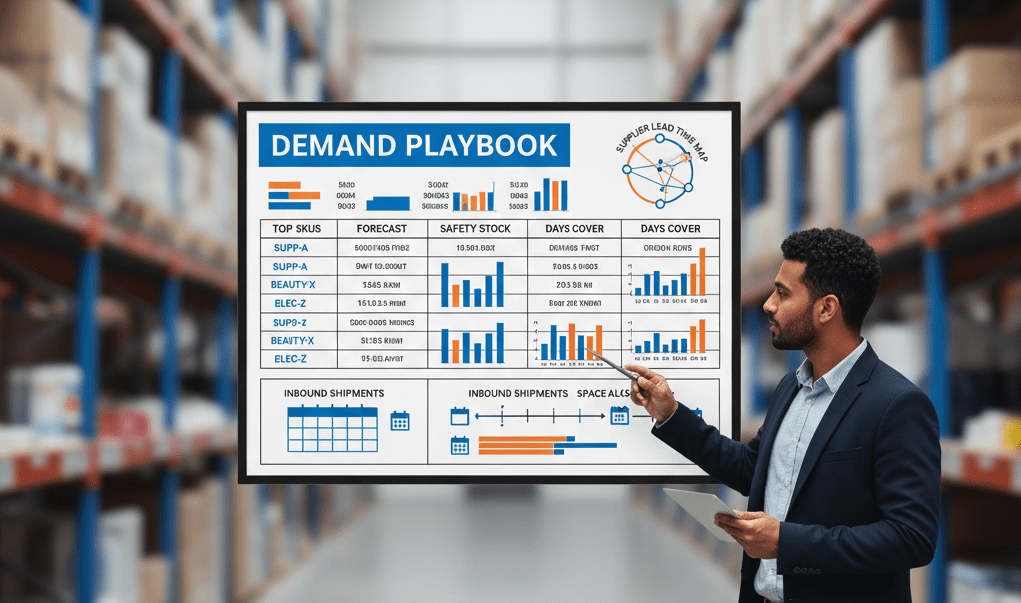

The 6 step demand planning playbook

1) Set one source of truth

Create a clean spreadsheet or report with the fields you need, SKU, variant, unit of measure, last 12 months sales, forecast by week, supplier lead time, minimum order quantity, safety stock, next inbound date. Keep it simple and consistent.

2) Forecast the top movers first

Focus on the 20 percent of SKUs that drive most orders. Use recent sales, season spikes, traffic plans, and promo calendars. Keep the math simple, average weekly demand with a sensible uplift for growth or planned ads.

3) Map real lead times

Ask suppliers for current lead times door to dock. Add customs or transfer buffer if you import. Track the actuals and update the plan when lead times change.

4) Set safety stock by risk, not guess

If a SKU is a hero or a promo item, give it higher coverage. If a SKU is slow and stable, lower coverage. Revisit these choices every month.

5) Place the plan on a calendar

Turn the forecast into buy dates and dock appointments. Book receiving slots so dock to stock does not slip. If volume is heavy, split inbound over several days and sequence by launch date or priority.

6) Review and adjust on a rhythm

Run a weekly huddle for fast movers and a monthly review for the long tail. Look at forecast error, stockouts, dead stock, and inbound delays. Adjust orders early, small changes beat last minute air freight.

Safety stock and service levels made simple

Pick a clear service goal for each class of item. For example, 98 percent for top movers, 95 percent for the middle, 90 percent for the tail. Translate that into days of cover based on volatility and lead time. If your supplier slips, raise cover. If demand is stable, lower it. Write the rule next to the SKU so everyone can see it.

Tip: When you change price or run ads, demand will shift. Update the forecast that same week. Small updates keep the plan honest.

Turn the plan into inventory and space

A forecast is only useful if it fits your warehouse, your carriers, and your cash.

-

Inbound flow: Align purchase orders with ASN details and carton labels so receiving is fast.

-

Space planning: Make sure the next inbound fits the assigned bins or racking. Use overflow plans in advance, not on the dock. See warehousing and storage solutions.

-

Picking effort: Slot hero SKUs near pack to cut travel. If you kit, reserve space and time for the build. See kitting assembly services.

-

Transportation: Match forecasted order peaks to carrier capacity and packaging rules to avoid DIM surprises. See discounted shipping rates.

-

Systems and visibility: Use dashboards for on hand, on order, and days of cover. Share alerts for low stock and late inbound. See real-time information.

A short monthly S&OP call can tie all this together. Invite operations, marketing, finance, and your 3PL lead. End with a decision, what to buy, how much, and when it lands.

Why Product Fulfillment Solutions

-

FEFO with lot and expiry at receiving keeps consumables fresh and reduces waste.

-

Dock to stock speed with barcode first receiving and strong ASN alignment.

-

Central U.S. hub in Cincinnati reaches most customers in 1 to 3 days by ground.

-

Pick and pack standards and right size packaging protect margin from DIM weight.

-

Kitting and light assembly for promos and subscription boxes.

-

Planning support that connects your forecast to inbound schedules, storage, and labor.

Strengthen your flow with 3PL fulfillment and ecommerce fulfillment, then layer in pick and pack services as volume grows.

FAQ

How far out should we forecast

Plan weekly for 8 to 12 weeks and monthly out to six months. Longer views are rough, focus on the next quarter.

What if supplier lead times keep changing

Track actuals. Raise safety stock for that supplier, split orders, or change the mix to protect your top movers.

How do promotions fit the plan

Add your ad and promo calendar to the forecast and lock purchase order dates in advance. Review the uplift a week after the promo and correct the next cycle.

Should we buffer for returns

Yes. If your category returns at 5 percent, add that to your build plan so good stock stays ready to ship.

Is there a quick win to cut stockouts

Yes. Forecast the top 20 percent of SKUs in detail and raise their safety stock to your target service level. You will feel the change in days.